3 Steps to Install Electric PDLC Film: (Smart Tint Electronic Glass Guide 2020)

3 Steps to Install Electric PDLC Film: (Smart Tint Electronic Glass Guide 2020)

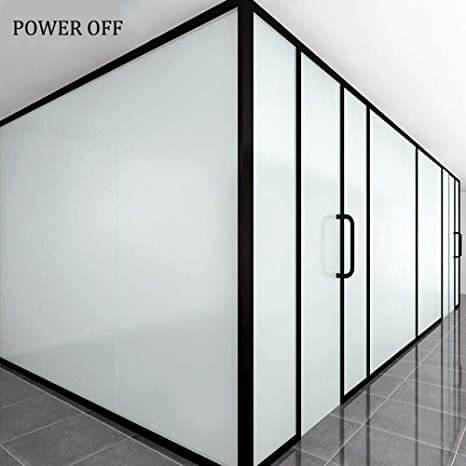

Transparency is the most obvious characteristic of electric pdlc film. But that does not mean that it needs to look like that in all installations. The evolution of the sector’s technology allows the material to act in ways never imagined years ago, such as controlling the privacy and the level of light entering the buildings (or even the lighting that passes from one indoor environment to another). There are different modern solutions that allow this.

Why Electric PDLC Film?

Insulated can get automatic blinds, polarized ones change the appearance from transparent to totally opaque? It can happen with the touch of a button and the electric control glasses also filter the light, not just the radiation. Not to mention other innovations that should soon arrive in China. Next, check out the main products aimed at these functions offered in the market and what benefits they can bring to an architectural project.

THE BENEFITS AND APPLICATIONS OF ELECTRIC PDLC FILM

It is common to see commercial and corporate buildings made of glass. Global warming, as we all know, has played an important role in increasing temperatures around the world. Under such circumstances, when the sun’s rays penetrate through the glass walls of a building, the temperature of the environment increases making it uncomfortable for the people inside.

Electric pdlc film has attracted a lot of interest in recent years to deal with this particular problem. The demand for these heat reflective films for glass has increased in the past decade or especially in the corporate and commercial sector. A pdlc film or Energy Efficiency film is a thin film that consists of several layers of materials that are designed to trap infrared light and prevent it from entering the room.

In how many shades electric pdlc film are available?

Electric pdlc films are available in various shades in a variety of light transmissions. Premier Film has a wide range of electric control films that meet the requirements and segments. They are highly common in corporate offices, banks, ATMs, shopping malls, hospitals, airports and the food industry. Electric control film is a high quality window film that offers customers an enhanced experience.

There are several benefits associated with applying heat reflective films to the glass. In addition to reducing the ambient temperature, it also retains heat during winters, making it suitable for all seasons.

Applications and benefits associated with applying electric control films:

Electric pdlc film is ideal for offices, homes and commercial spaces. Moreover, you can use to any glass surface. The concept of such films is truly a revolutionary idea, as it improves overall comfort. There are no disadvantages when the film goes for installation.

There is no loss of natural light compared to colored and reflective films. In addition, such films attract great interest from food retailers and are great for projects that use a lot of glass.

Reduce air conditioning bills

Reflective heat films for glass have several benefits; one of them is a significant savings in air conditioning bills. As the heat reflective films lower the ambient temperature by a few degrees, it helps to change the air conditioning bills.

Procedures for installing electric pdlc film

Step 1: Connect the bus bar to the switchable film

Generally speaking, a transport bar is an electrically conductive bar, bar or strip.

In relation to Smart Film, the bus bar is a conductive copper strip applied to one or two edges of the PDLC film sheet before being laminated between two glass plates.

The copper strip acts as a conduit for the stepped electric current (48 / 60V AC). It activates the liquid crystals within the film. We diffuses the current by means of a conductive coating of indium tin oxide on the surface of the attached PET film.

Some electric pdlc film panels may require more than one bus bar to ensure complete and even distribution of electrical current.

Twin threads

The wires solders to the ends of each bus bar. They are twin (or double) threads. This apparent ‘doubling’ is to compensate in the event that a wire comes off or comes off during the panel installation process. The bar can be applied to the long or short edge / s, depending on the needs.

Step 2: silicone edge sealant

For added safety or when using film in a high humidity environment use non-acidic silicone (e.g. GE-83) along the edges of the film about 5mm, when it dries (about 3 days) after power on and use the switchable film.

Step 3 with 3M glue to seal the edge

Kindly Note:

1, no water using in the installation unless to clean the glass

2, the needed electric pdlc film size is 2-3mm less than the glass size to fit the installation

3, everything should work under the dust-free environment.

4, remember to use silicone sealing glue

How to customize environments with window films?

Advantages of electric pdlc film

But the advantages of window films are not just practical. They are in fact able to literally change the face of the rooms, breaking the monotony of anonymous furniture and revitalizing the spaces. The customization possibilities of this type of solution are practically endless.

It is possible to choose from a very wide range of colors and shades, as well as decide which effect to give to the glass. From the classic satin finish to the most original decorations, up to the simulations of other materials. It is also possible to choose a decoration – photo, painting, graphic – and “transfer” it to the film.

Get the correct amount of light with window films

Window films, at home, but also in the car, can play a valuable role in regulating light intensity. In fact, the blackout version is able to let in the external light. Moreover, it reduces the incoming heat and preventing the dazzling effect.

Hence, it is a source of considerable annoyance both in the home and in the workplace. In fact, the film acts as a filter, reflecting harmful rays. Moreover, it cuts the amount of light radiation and, if desired, also the load of UV rays.

How to increase safety with electric pdlc film?

Finally, thanks to the application of the films it is possible to guarantee maximum safety in case of glass breakage. The adhesive film is in fact able to keep the broken glass together. Similarly, it avoids flying splinters or, worse, sharp edges. The films easily work on glass already present in the rooms in order to make them immediately comply with current safety standards.

Conclusion

With the development of science and technology, people are applying hi-tech products to their life. Especially when decorating, electric pdlc film is popular. Switchable film is a polymer liquid crystal film (PDLC film). It offers people privacy, projection, security, etc.

Well, there are still many people in doubt, is it functional? Where are they applied? We have come up with the latest pdlc smart film solutions. Find latest electric pdlc films under your budget.